Why is ferrosilicon manganese a popular ferroalloy for steelmakers?

According to the latest data from the US Geological Survey, Ferro Silicon Manganese is the most widely used ferroalloy in the world after ferrochrome. This ferroalloy is also the second most traded product in the world.

Advantages of Ferro Silicon Manganese Ferroalloy

Ferrosilicon-manganese compounds provide the properties of ferrosilicon and ferromanganese in steel production, maintain the molten composition, and add less phosphorus, carbon, sulfur, and nitrogen to the steel than ferrosilicon and ferromanganese.

Oxidation with ferrosilicon manganese leads to the production of cleaner steel because liquid manganese silicate coagulates and separates more easily from the melt.

Moreover, from the perspective of fluid dynamics, Si is obtained through SiMn more than it is obtained through Fe-Si. The use of ferrosilicon manganese is economically efficient, and it is much cheaper than other ferroalloys, which makes it easy to replace high-carbon ferromanganese and ferrosilicon chosen by the steelmakers in the past.

However, the effect of adding ferrosilicon manganese to steel depends on the amount of ferroalloy added and its combined effect with other alloying elements. This ferroalloy does not fall into the category of dangerous goods for transport, is corrosion-resistant, and can be used with certain types of chemicals or in coastal areas.

The Position of Ferrosilicon Manganese in Trade

Not only is Ferrosilicon manganese the most consumed one in industry, but it has also gained the second rank in trade because it is not easy to access raw materials and energy costs are very high, leading many countries to import this ferroalloy instead of producing it. Europe is the world's largest importer of silicon manganese.

An average of 2 million 652 thousand tons of silicon manganese was traded between 2001 and 2016, the highest amount of which occurred in 2007 at 3 million 379 thousand tons.

In 2009, with the onset of the financial crisis, the global trade trend of silicon manganese declined, but this decline was fully restored in the following years. Finally, in 2016, with an annual growth rate of 2.7%, it reached 2 million 675 thousand tons

Ferroalloys and Smelting Additives

Ferroalloys and Smelting Additives Consumable and Refractory

Consumable and Refractory Natural rubber

Natural rubber Rubber raw materials

Rubber raw materials synthetic rubber

synthetic rubber Other equipment

Other equipment low voltage

low voltage Industrial Electrical Tools

Industrial Electrical Tools  Instrumentation

Instrumentation Soft Starter

Soft Starter inverter

inverter All kinds of wires and cables

All kinds of wires and cables electric motor

electric motor Industrial Chains

Industrial Chains Radial Shaft Seals

Radial Shaft Seals Straps

Straps Cutting Tools

Cutting Tools Manual Tools

Manual Tools Motor Tools

Motor Tools Safety Tools

Safety Tools Welding Tools

Welding Tools industrial gauge

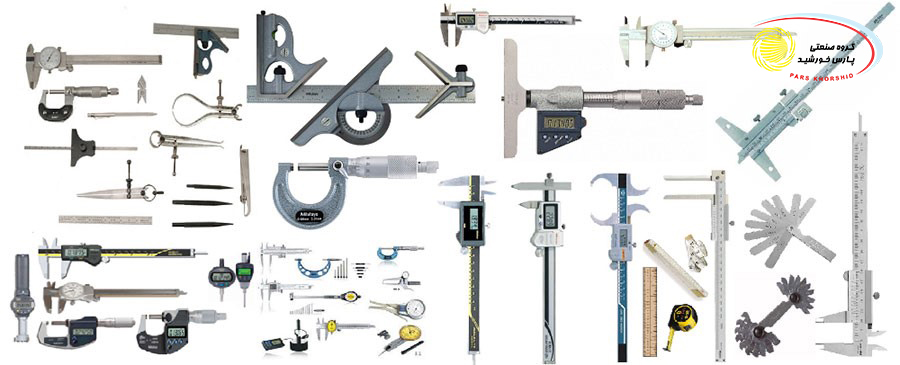

industrial gauge Measurement-Tools

Measurement-Tools Load chains

Load chains Crane

Crane plastic materials

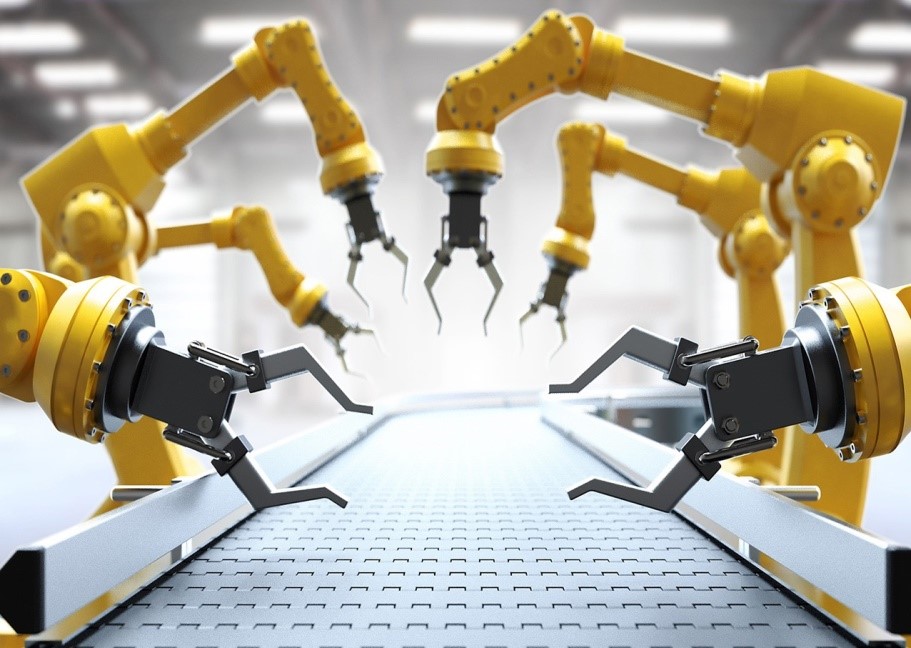

plastic materials HMI

HMI PLC

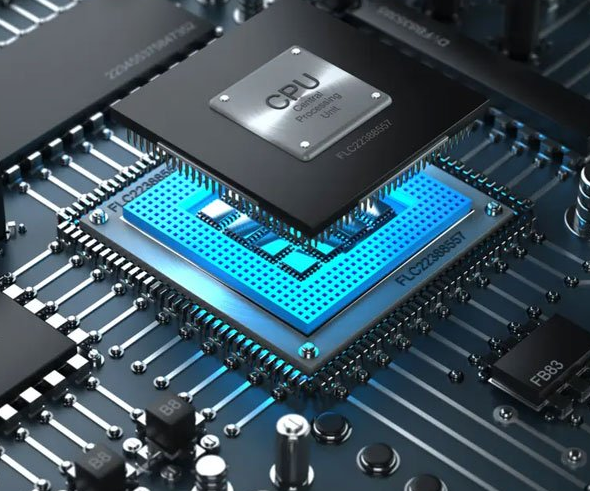

PLC CPU

CPU Programmable logic controller(PLC)

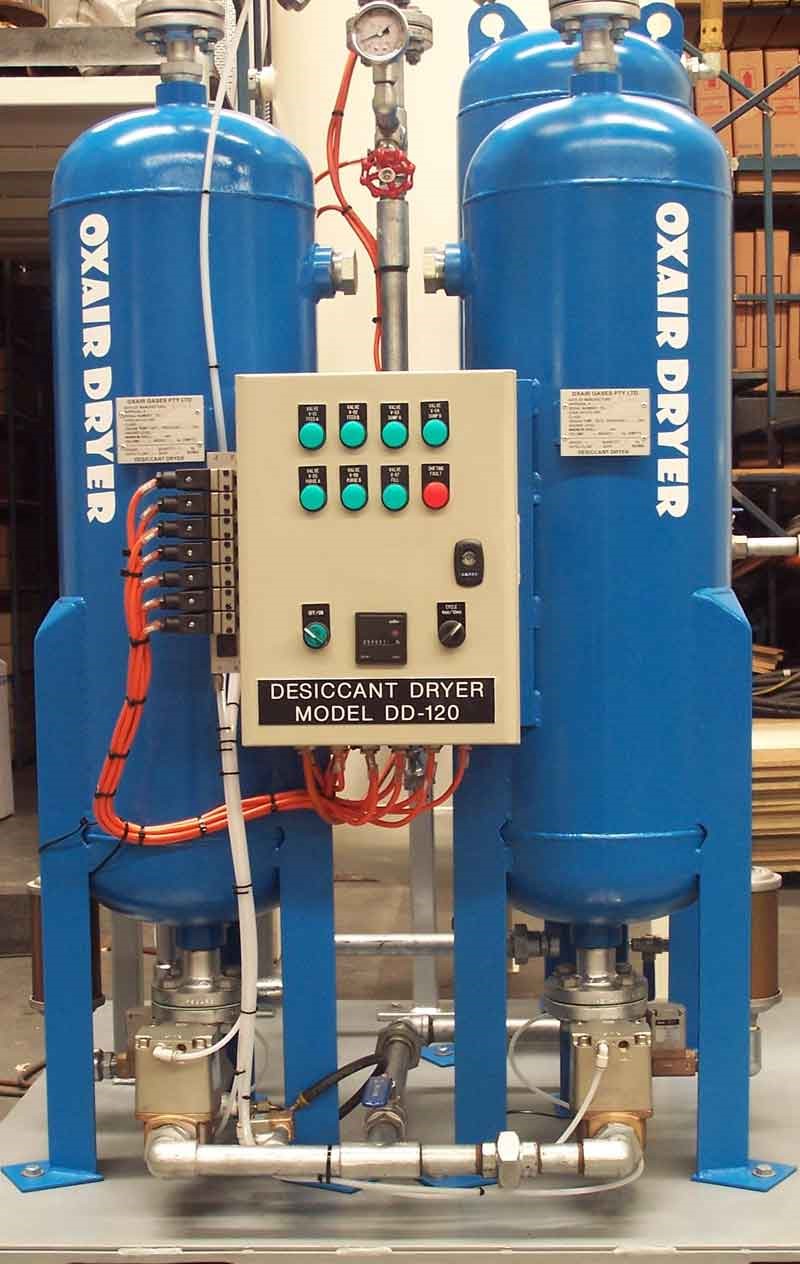

Programmable logic controller(PLC) Membrane Dryers

Membrane Dryers Water Separator

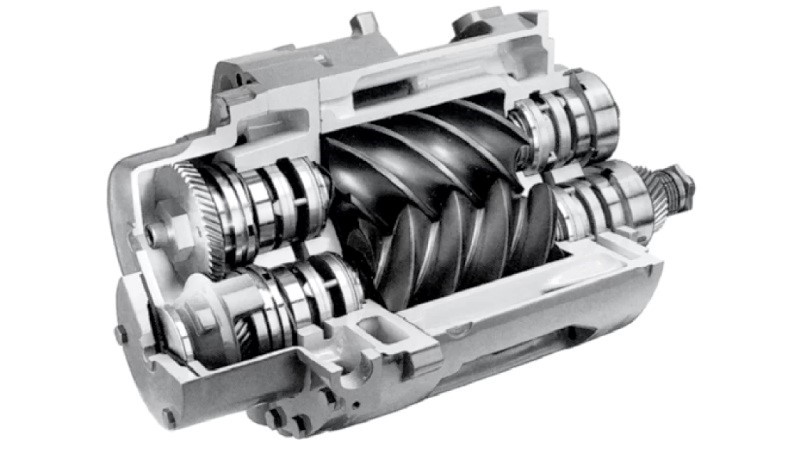

Water Separator airend compressor

airend compressor adsorption dryers

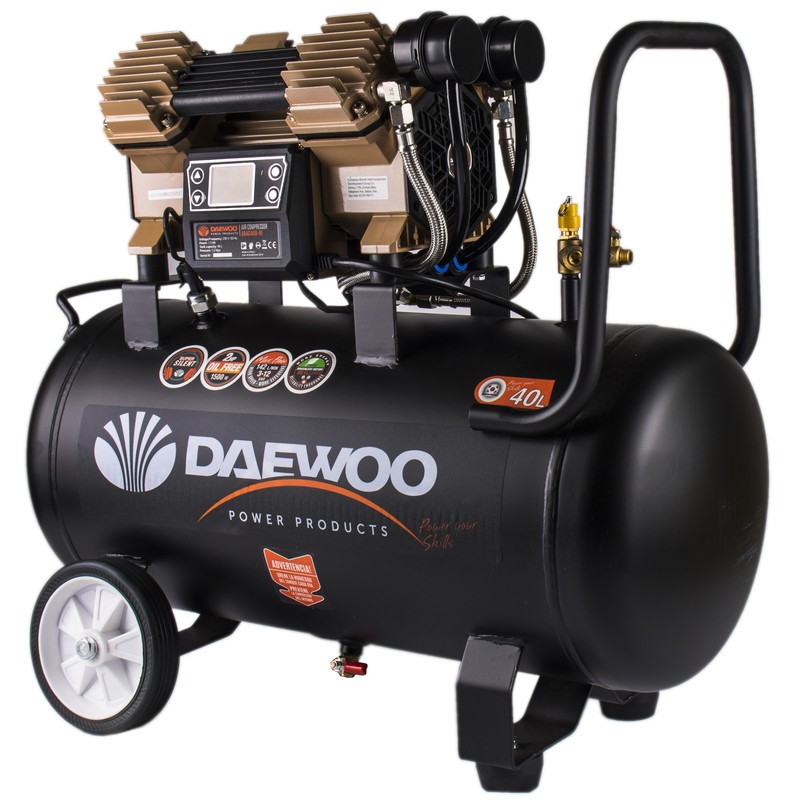

adsorption dryers Compressor

Compressor microfilter compressor

microfilter compressor air end compressor

air end compressor Roller Bearing

Roller Bearing Ball Bearings

Ball Bearings