What is natural rubber? (3)

What is natural rubber? (3)

In the ‘What is natural rubber?’ blog post (1), we talked about the history of the discovery of rubber and its source of production, and in the article, ‘What is natural rubber?’ (2), we examined how this material is produced and its chemical structure; now we turn to its properties, usage, its difference with synthetic rubber, and its market share.

Properties of Rubber

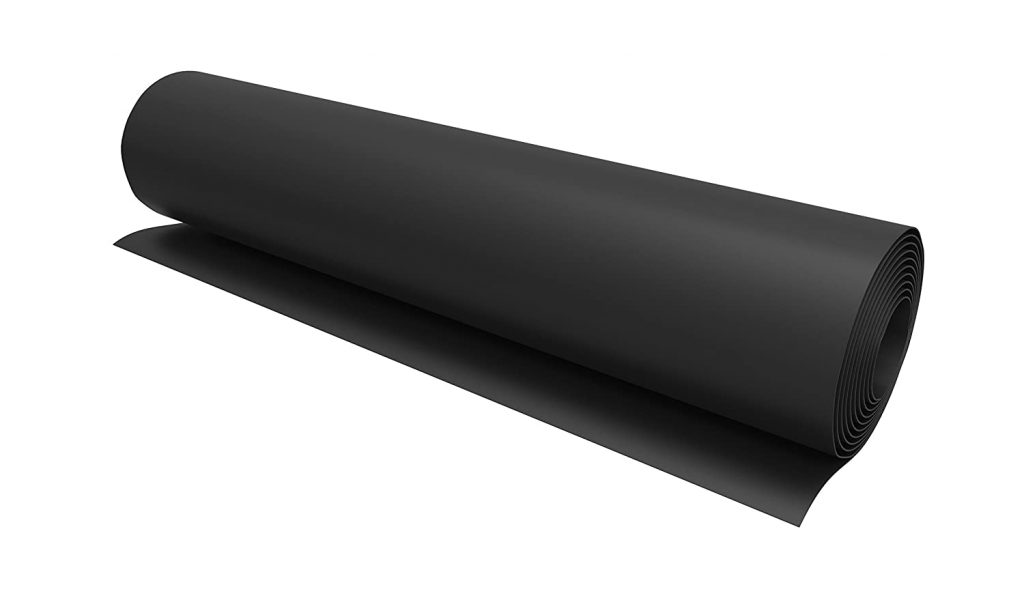

Natural rubber is the most widely used raw material of rubber because it has high tensile strength, excellent abrasion resistance, low damping ration, adhesion, longitudinal, transverse, and thick (elasticity) tension properties. Natural rubber is very flexible and is resistant to water, some chemicals, cutting, tearing, wear, and fatigue apparatus dynamic. It has high tensile strength and easily adheres to other materials.

However, natural rubber is not as resistant to heat, light, and ozone as other rubbers such as neoprene (due to the double bond in each duplicate unit); its resistance varies according to the type of tree it is taken from, and it also includes natural impurities.

Good elasticity (ability to recover shape after deformation); Good electrical insulation; Low internal friction; Resistance to most mineral acids, salts, and alkalis are other characteristics of natural rubber.

However, they show little resistance to petroleum products, such as oil, gasoline and naphtha, and non-polar and hydrocarbon solvents, as well as flame and ignition, and lose their strength at high temperatures; therefore, it is recommended not to use them at 80°C (175°F). They also decompose rapidly in direct sunlight as long as they do not contain certain compounds.

Usage of Rubber

Rubber is a very important material in modern life, which, due to its extraordinary elastic properties, is used to make a variety of products, including hospital supplies, home appliances, and toys.

The most common use of this material (more than 60%) is in the manufacture of tires (tire tread, tire body, and profile).

Other usages: rubber sealants and water stops, pipes, shock absorbers, rubber sponges for furniture and mattresses, rubber sheets, rubber bands, belts and conveyors, hoses, washers, shoe soles, sporting goods, seals, adhesives, pacifiers, tubes, special industrial parts, vulcanized parts and anti-wear parts, many medical usages (gloves, etc.), engineering usages (flexible joints, cushions for stairs and buildings), etc.

The Difference between Natural and Synthetic Rubber

Natural rubber is taken from the sap of certain trees and is used after some processing. But synthetic rubber contains any type of synthetic elastomer. They are polymers made from petroleum by-products. About 32 million tons of rubber are produced annually in the United States, of which two-thirds are synthetic.

Global revenue from the production and sale of synthetic rubber is likely to reach $ 56 billion by 2020. The synthetic type, just like the natural type, is frequently used in the automotive industry, door and window profiles, seals such as O-rings and washers, hoses, belts, mattresses, and floors.

Synthetic rubbers offer a variety of physical and chemical properties; therefore, they can improve the reliability or usage of a particular product. Synthetic rubbers are superior to natural rubbers in two main aspects: thermal stability and resistance to oils and related compounds. For instance, they are more resistant to oxidants such as oxygen and ozone, which reduce rubber life.

Natural rubber is used in cases that require high resistance to abrasion and heat. Due to its strength and compressibility, natural rubber is used in engineering applications such as anti-vibration bases, actuator couplings, springs, bearings, rubber bands, and adhesives. But most of them - 50% natural rubber - are used in high-performance tires for race cars, buses, and airplanes because of their strength and heat resistance. These compounds are also used in hoses, automobile parts, floor mats, and battery boxes. The adhesive properties of natural rubber are even used in rubber cement and soil stabilizers used on new roads. Even raw rubber is sometimes used as an adhesive and as part of a shoe sole. In addition, about 10% of latex harvested from trees is simply reduced to 60% rubber solution for the production of products such as latex gloves or using as a cover.

Rubber, Production, Market Share

In 2017, more than 28 million tons of rubbers were produced, of which approximately 47% are natural. Since most of the rubber produced in the world is synthetic rubber and is obtained from oil, the price of natural rubber is largely determined by the world price of crude oil. In 2005, Asia was the main source of natural rubber production, accounting for about 94% of it. The three largest manufacturers in Thailand, Indonesia, and Malaysia, together account for about 72% of total natural rubber production. Natural rubber is not widely cultivated in its native continent, South America, due to fire blight and other natural predators.

In 2019, the global market size for natural rubber was $ 23.56 billion and is expected to reach $ 27.87 billion by the end of 2026, with a compound annual growth rate of 2.4%. The main reason for this large market size is the growing demand for natural rubber products due to the growing automobile industry.

Ferroalloys and Smelting Additives

Ferroalloys and Smelting Additives Consumable and Refractory

Consumable and Refractory Natural rubber

Natural rubber Stearic acid

Stearic acid

Rubber raw materials

Rubber raw materials synthetic rubber

synthetic rubber plastic materials

plastic materials Chemical additives

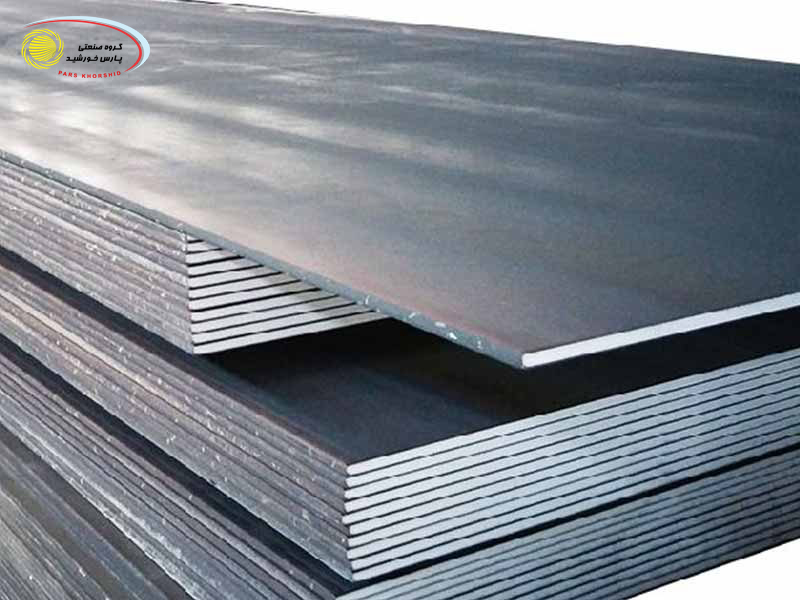

Chemical additives Steel sheet

Steel sheet Industrial Chains

Industrial Chains Radial Shaft Seals

Radial Shaft Seals Straps

Straps Cutting Tools

Cutting Tools Manual Tools

Manual Tools Motor Tools

Motor Tools Safety Tools

Safety Tools Welding Tools

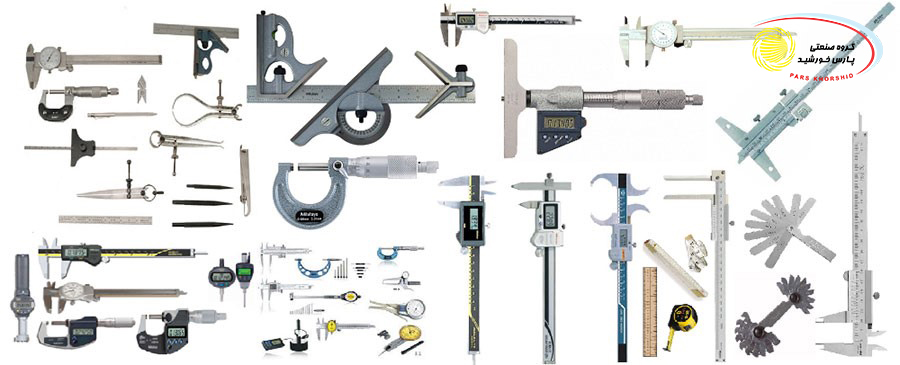

Welding Tools industrial gauge

industrial gauge Measurement-Tools

Measurement-Tools Load chains

Load chains Crane

Crane